Stud removal by Portable CNC Machining

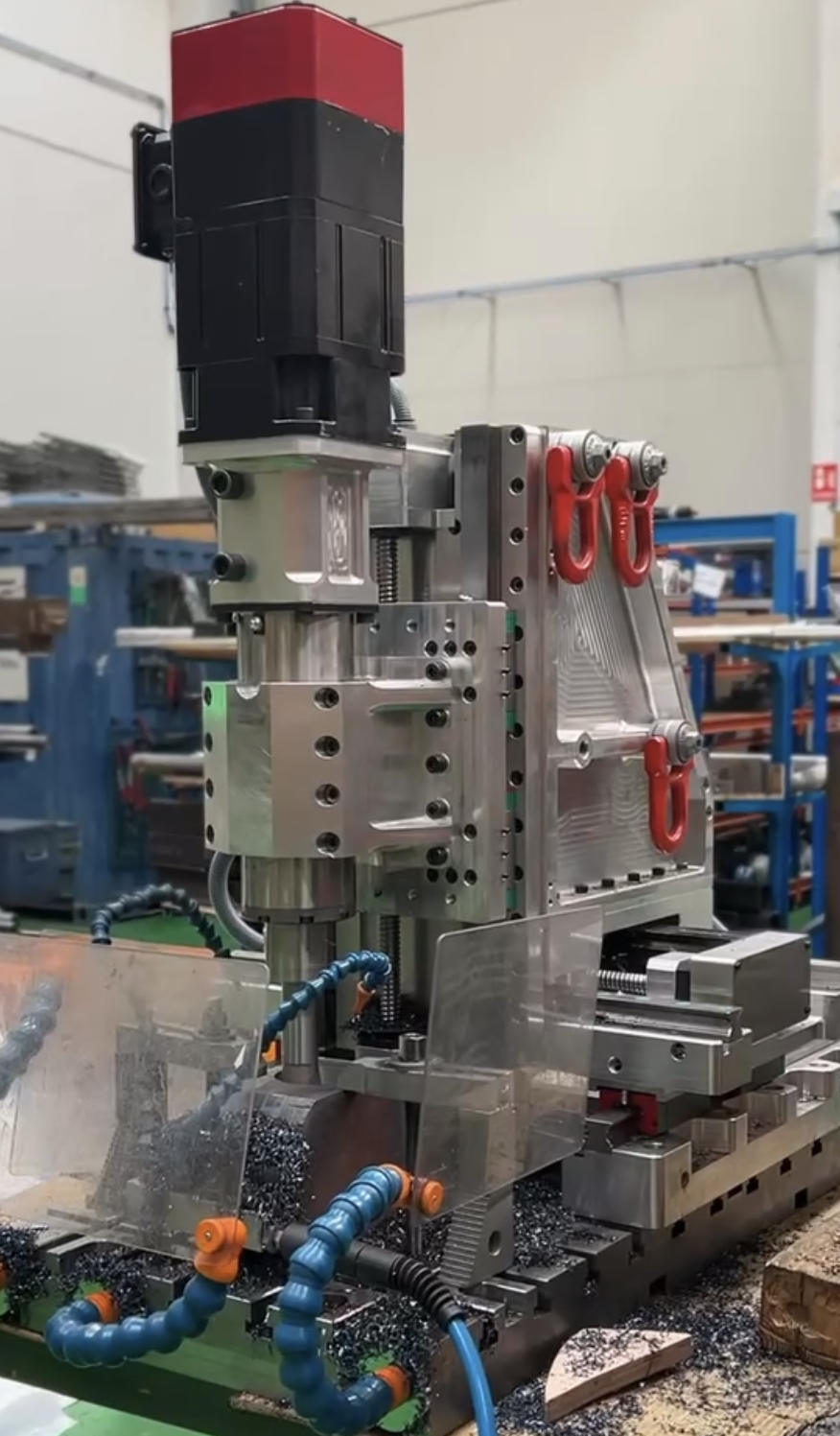

Stud Removal by Portable CNC Machining

Portable CNC machining is a high-precision process that allows controlled material removal directly on site, without the need to dismantle the equipment or transport it to a workshop.

Using portable CNC equipment, the seized or damaged stud is progressively removed through controlled milling or drilling operations, ensuring a safe and accurate intervention. The process enables complete removal of the stud while preserving adjacent surfaces and internal threads, provided their condition allows it.

Thanks to numerical control, the machining accuracy is very high, minimizing the risk of damage to the parent material. The process is carried out in a controlled manner, avoiding excessive mechanical stress or impact that could compromise the integrity of the component.

The working range is wide, covering small fasteners starting from M3 up to large diameters (M200 and above), with tooling and cutting parameters adapted to each specific application.

Portable CNC machining is a fast, safe, and highly effective method for removing seized or damaged studs, reducing downtime and optimizing intervention schedules.

Aplications

Stud removal in gas and steam turbine casings.

Removal of studs in pressure equipment, heat exchangers, pumps, and other equipment in the petrochemical sector.

Stud machining and extraction in turbine shafts (gas, hydro, and thermal sectors).

Cutting and machining of seized pins and shafts in the naval, energy, petrochemical, and automotive sectors.

On-site thread recovery and resizing using portable CNC machining.

Drilling operations and machining of special geometries or complex shapes